Products

RF/DC Magnetron Sputtering System

- Single as well as multi target sputter source option

- Sputter configuration available from 1-6 Sputter sources in sputter up or sputter down

- Suitable for co-deposition as well as sequential deposition

- Customize combination available base on process requirement

- Compact foot print for better utilization of available space

- Manual, semi-automatic or fully automatic mode

System Features

- Material: SS304, SS304L, SS316

- Geometry: Cylindrical, Box type, D-shaped, Spherical

- High vacuum pumping system: Cryo pump, Turbo Molecular pump, Diffussion pump

- Base pressure: 10-7 torr by using suitable capacity turbo molecular pump

- Electro-polished process chamber from inner and outer side for better vacuum performance

- Extra ports for future up-gradation as per user requirement

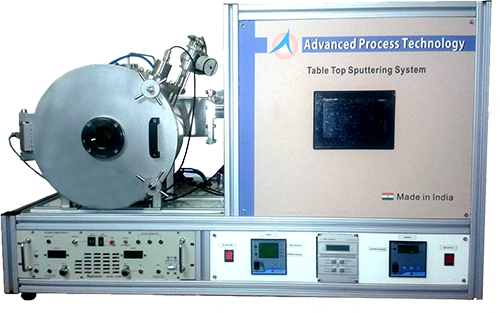

Table Top Sputtering System

- Two Target DC Sputtering System

- Confocal Sputter configuration

- Suitable for co-deposition as well as sequential deposition

- Compact foot print for better utilization of available space

- Manual, semi-automatic or fully automatic mode

System Features

- Turbo Molecular pump based high vacuum pumping system

- Base pressure: 10-7 torr by using suitable capacity turbo molecular pump

- Electro-polished process chamber from inner and outer side for better vacuum performance

- Extra ports for future up-gradation as per user requirement

SEM Sputter Coater

SEM sputter coater suitable for SEM, TEM and other thin film applications. Compact easy to operate table top model suitable for SEM sputtering with noble metals like Au, Pd, Au/Pd, Pt.

Thermal Evaporation System

“APT Make Thermal Evaporation Systems designed for vacuum evaporation of metals on to a substrate with single or multiple evaporation sources and the evaporation would be done in a high vacuum contamination free chamber”

E Beam Evaporation System

“APT Make E Beam Evaporation Systems designed for Electron Beam Evaporation of materials on to a substrate with E Beam sources and the evaporation would be done in a high vacuum contamination free chamber”

RTP Furnace

Rapid Thermal Processing furnace for a wide range of applications in small scale production. The Jetlight is a compact and robust RTP furnace.